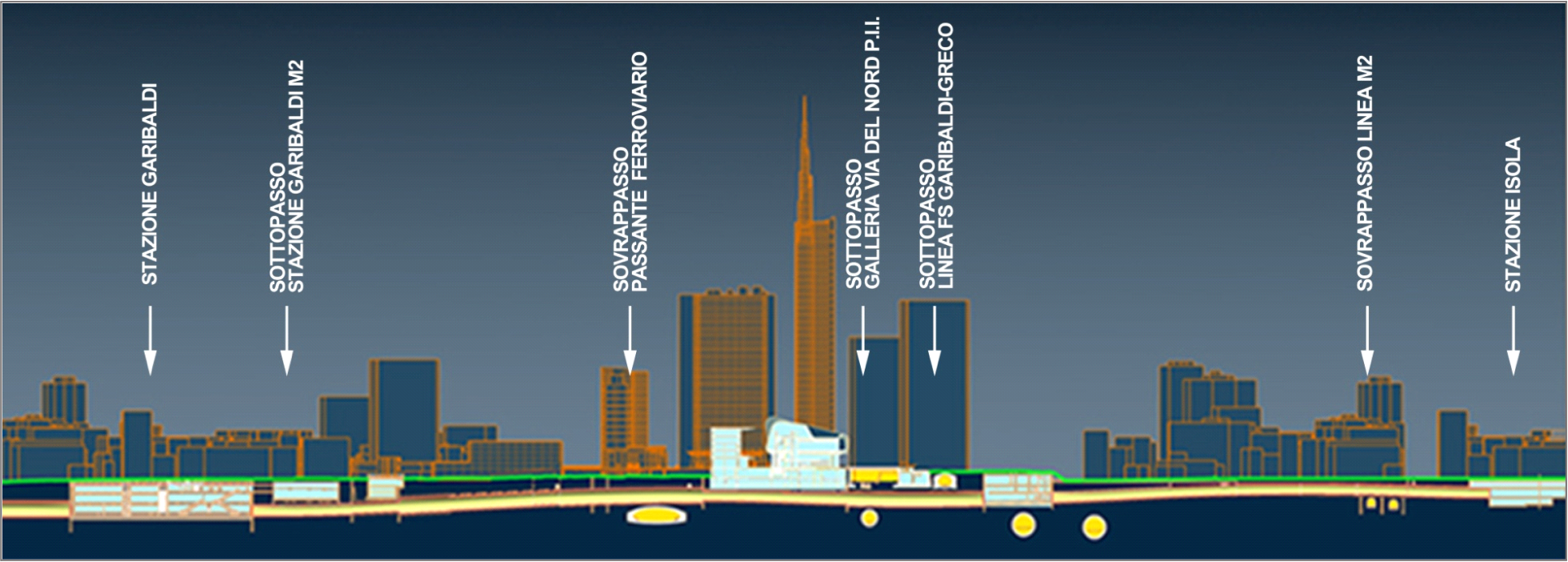

Milan Metro Line 4 (Italy)

Milan Metro Line 5 (Italy)

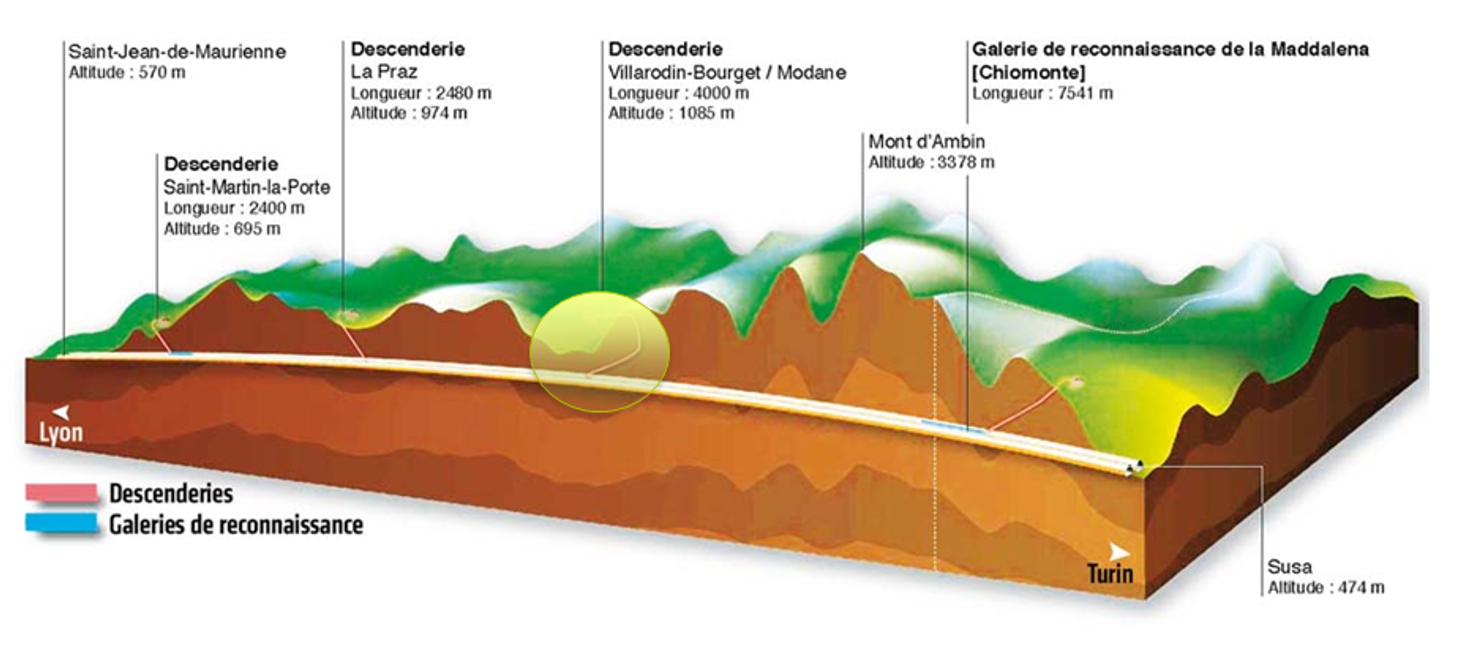

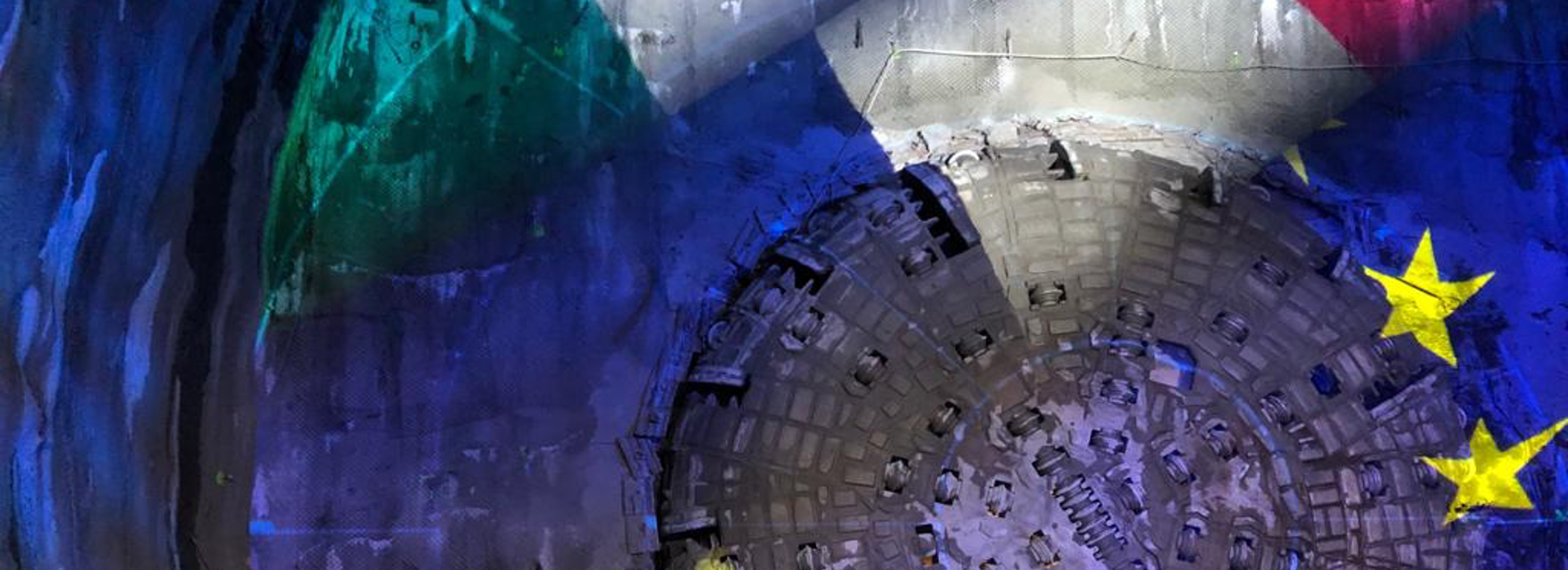

Railway line Turin Lyon – Avrieux ventilation shaft – (France)

Railway line Turin – Lyon, access tunnel of Saint Martin la Porte (France)

Cityringen Metro Copenhagen – Denmark

Istanbul Metro Line – Turkey

S.S. N. 1 Aurelia Bis – Road By Pass – Sanremo, Italy

Tunnel Des Oudayas in Rabat (Morocco)

The construction of the new tunnel designed by Alpina allowed, through the underpass of the Rabat fortress, to divert the traffic under one of the city’s main thoroughfares, separating the Kasbah from Medina.

Continue reading